Micromechanics

Micromechanics

133. Detectors, private collection

Hitachi High-Tech Analytical Finland Oy manufactures semiconductor detectors for XRF devices, among other products. Micromechanics/watchmakers assemble the detectors in clean rooms by hand, under a microscope. The work requires micrometer precision and spatial awareness. In addition to detector assembly, the job involves significant development of production methods and products, as well as the creation, maintenance, and calibration of various tools and testing devices.

Here are various detectors from over the years, used in different applications.

In component production, where detectors, lasers, and spectrometers for LIBS devices are manufactured, nine micromechanics or watchmakers who graduated from the Watchmaking School are employed.

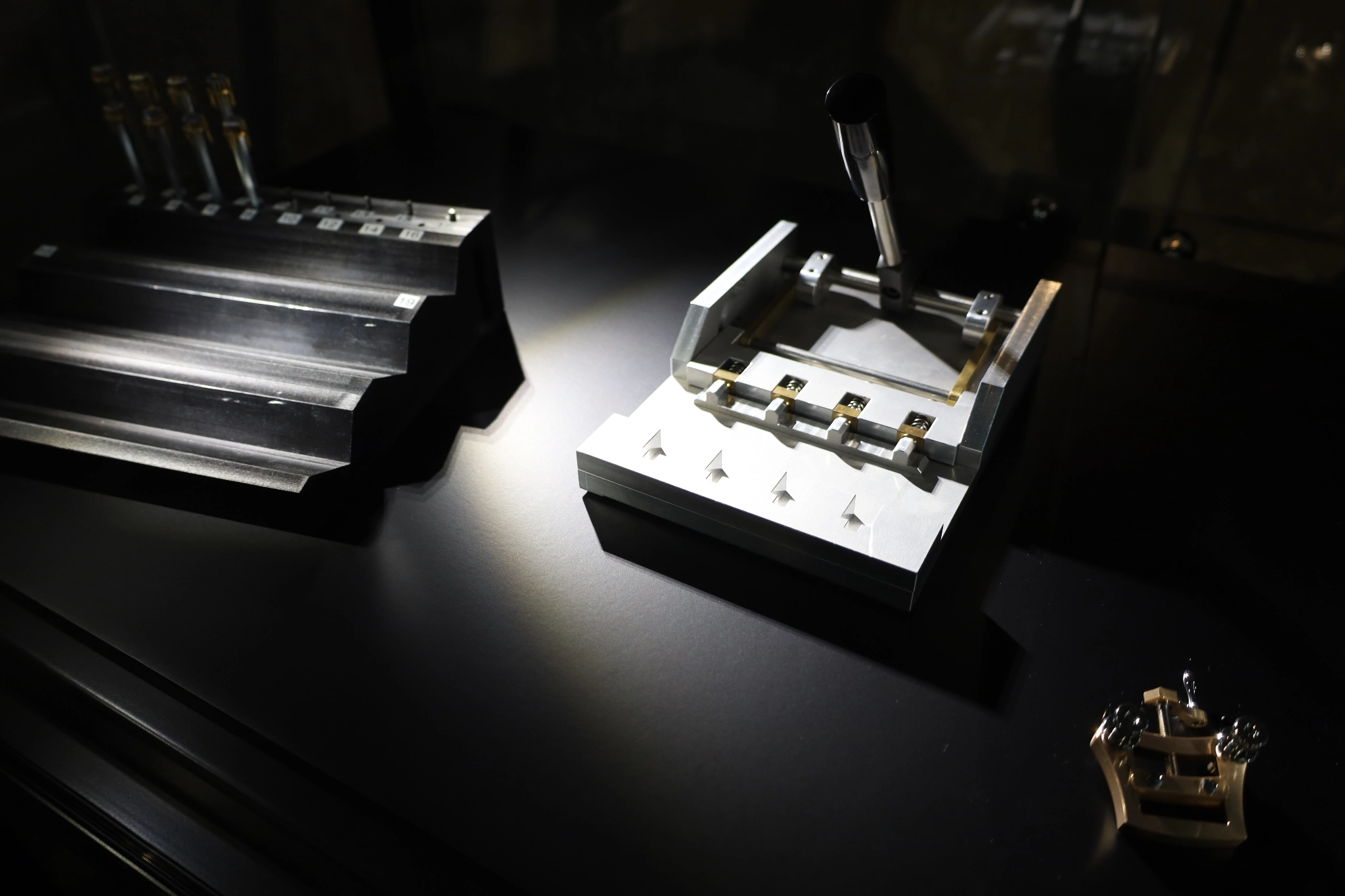

134. Assembly jig, private collection

Used for aligning and holding parts together for screwing.

135. Surface grinder, bronze, stainless steel, private collection.

136. Finished gear, stainless steel, used in gear mechanisms, private collection.

137. Small fork anvil, stainless steel, private collection.

138. Visa Männistö, Kowa outer casing, private collection

Whitepoint Optics manufactures modern cinema lenses from vintage photography lenses. All mechanical parts of the old lens are disassembled, and the lenses are mounted into a new body, preserving the distinctive features of the vintage lenses.

This is the outer casing of a Kowa lens, now removed during maintenance. The mechanics of the outer casing allow for continuous focusing and aperture control during filming. The technician’s job is to fit the outer casing parts together with hundredth-millimeter precision and assemble the product. When done correctly, the focus and aperture controls feel smooth and light to use. Currently, 19 micromechanics or watchmakers who graduated from the Watchmaking School work as technicians and in other roles at Whitepoint Optics. This outer casing was crafted in 2020 by Visa Männistö, who graduated as a micromechanic from the Watchmaking School.