History

History

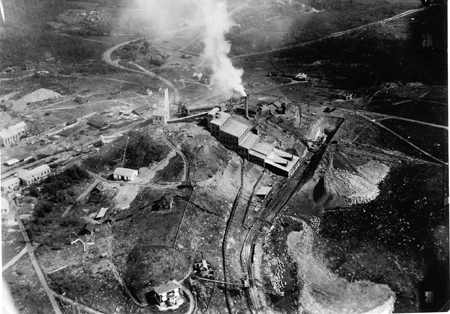

Over the decades, the Outokumpu mine developed into the most significant center of mining industry. The Outokumpu mine included several mines and production facilities throughout its history, such as Keretti, Vuonos, the so-called Old Mine, Hammaslahti, as well as the early copper factory and related smaller ore extraction sites.

The main product of the Outokumpu mine was copper concentrate, which was further processed in other locations. An exception in the processing was the Outokumpu copper factory, which operated from 1913 to 1929.

Discovery of Outokumpu ore

In 1908, while dredging the Kivisalmi shipping channel, a large yellowish stone was found. A sample sent to the Geological Office in Helsinki contained a significant amount of copper. The research work was led by geologist and mining engineer Otto Trüstedt, who concluded that the boulder was a stone released from the actual ore by the Ice Age. Initially, copper ore was searched for in the vicinity of Rääkkylä, but eventually, the investigations led to the Outokumpu area.

The investigations focused on the rock types contained within the boulder and those found nearby. These clues brought Trüstedt to Outokumpu. Copper ore had to be sought through test excavations and drilling. After nearly two years of searching, on March 17, 1910, the diamond drill bit pierced a vein of copper ore. The treasure of Outokumpu had been found.

Mining Operations Begin

Mining operations in Outokumpu started with test mining and additional exploratory drilling in 1910, but soon the exceptionally rich ore concentrations enabled mining aimed at economic profits.

Outokumpu's copper contained an average of 4% copper, 28% iron, 25% sulphur, 1% zinc, and 0.20% cobalt. The ore contained 0.80 grams of gold and 9 grams of silver per ton of ore.

Outokumpu's first industrial ore processing plant was a copper factory built into the slope of the strange hill, which began operations in 1913. The copper ore mined from underground was processed into ingots, wires, and nails. Some of the ore rocks were transported to a port, either to Joensuu or closer to Juojärvi's Pitkälahti.

The difficulties in the early stages of mining led to Norwegian ownership of the mine in 1917, but after they relinquished control, operations returned to Finnish hands in 1921. At the same time, the headquarters of the mining company was moved to Outokumpu, where it operated until the late 1940s.

Until the end of the 1920s, ore was extracted from three locations in Outokumpu, named Kumpu A, Kumpu B, and Kumpu C (Kaasila mine). The completion of the old mine displaced these smaller early mines.

The Outokumpu mine is developing and growing

In 1921, Eero Mäkinen was appointed as the CEO of the Outokumpu mine, who noted the need for new, efficient production facilities. These were implemented in the late 1920s, at which point the mine's operations began to revive.

New modern mining methods increased the production levels of the Outokumpu mine. In 1929, the extraction of raw ore exceeded the 100,000-ton mark for the first time. The quality of copper concentrate improved, and the market price of copper was favorable at that time. After the Outokumpu company recovered from the global depression, it was converted into a limited company in 1932.

The period from 1930 to 1950 was a time of strong growth for the Outokumpu company. The company opened new production facilities across Finland. However, the Outokumpu mine was the backbone of the entire company's operations. The number of employees at the Outokumpu mine alone grew from 932 in 1937 to 1,142 by 1953. As late as 1955, nearly 90% of the mining company's copper production came from the Outokumpu mine, and Outokumpu Oy became one of Europe's most important copper producers.

Keretti opens

The profitable mining of the remaining ore required a new shaft, so Keretti was established on a flat sandy ridge. Mining methods were also improved to be more efficient and safer. New production facilities equipped with efficient machinery—a crusher and a high-quality concentration plant—were built in conjunction with the mine shaft. The main products of the Keretti concentration plant were copper and sulphur concentrates. Important by-products included zinc and cobalt.

At time of completion, the Keretti shaft tower was the tallest in Europe, an impressive 96 meters. When production at Keretti started in 1954, it was the second largest copper mine in Europe. At the same time, the end point of Outokumpu's mining operations was estimated: copper ore was considered sufficient for 25 years.

Keretti made the Old Mine obsolete. The old mine tower became an observation tower in the late 1960s, and at the beginning of that decade, a mining exhibition was established at the base of the tower. The entire area was converted for tourism use in the mid-1980s. After Keretti was completed, ore hoisting also ceased at Mökkivaara.

The beginning and end of the Vuonos mine

Outokumpu Oy's prospectors found a new copper ore deposit about five kilometers from the center of Outokumpu in 1965, and production facilities and ore extraction were started there in 1971. A nickel open pit was also constructed in connection with the mine, which operated from 1972 to 1977. The Vuonos mine was closed in 1985.

The ore is depleted

More efficient mining machines and processing methods accelerated extraction, and the ore reserves inevitably dwindled. When Keretti closed, Outokumpu Oy had expanded into an international corporation.

The last shift left Keretti on May 25, 1989. Outokumpu's 79-year history as a mining town had come to an end. However, Outokumpu will always remain the birthplace of the modern Finnish mining industry.