How does the mine work?

How does the mine work?

Mining consists of several different phases.

Mining starts with scaling. This is done to keep the work area safe. Scaling by hand is done by using a long rod to drop all the loose rock from the walls and ceiling.

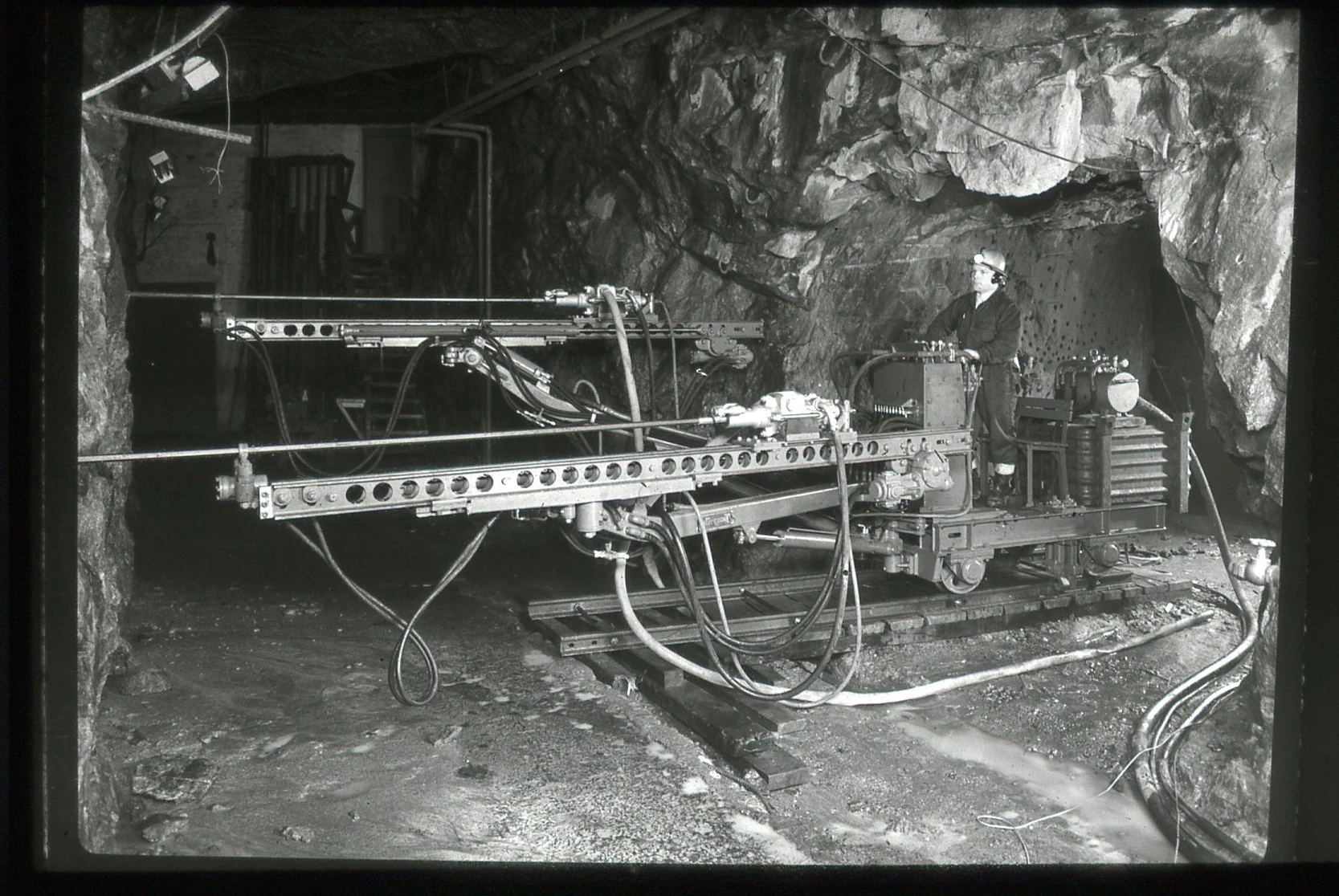

The next step is drilling. Holes are needed in the rock wall so that you can use explosives to crack the rock. The holes are drilled in an optimized schematic for the type of rock that is meant to be extracted.

When all the holes are drilled, they can be charged. The drilled holes are charged with explosives to crack the rock. There are several different explosives and several different detonators that can be used. The goal is to crack the rock and have the wall fall out onto the ground.

When the explosion has dropped the wall onto the ground in front of it, loading can begin. Loading can be done by hand or with machines. Machines are more common in modern mining. The rock is loaded and dropped down a loading shaft.

At the bottom of the loading shaft the rock is packed into some form of transportation. At the Outokumpu mine, this transportation took the form of ore trains. In Vuonos the transport was with a conveyor belt. The ore is transported either to the tower shaft or up above ground as it was in Vuonos. In Keretti the rock was dropped into a primary crusher before it was hoisted up the shaft.

The hoisted ore proceeds to the concentration plant, where one of several different concentration methods are used, depending on the ore type. The Outokumpu mine used flotation from 1928 onwards.

After going through the concentration process, the concentrate is dried and transported to smelting.